In today’s fast-paced global food and meat industry, effective cold chain management is non-negotiable. From farm to fork, it’s crucial to preserve the quality, safety, and integrity of perishable products at every stage. Here are the top 5 considerations to achieve a seamless cold chain:

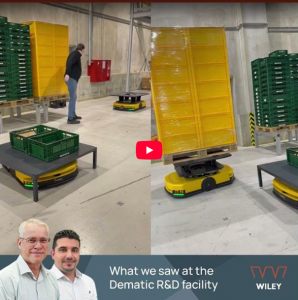

(1) Automated solutions for efficiency—Streamline operations and reduce handling with advanced systems like Automated Sorting and Retrieval (ASRS) for increased speed, accuracy, and compliance.

(2) Sustainability and energy—Assess insulation types and energy efficient refrigeration systems to achieve lowest operating costs and sustainability targets.

(3) Flexibility for growth—Master plan your facility and consider multi-temperature rooms for flexibility.

(4) Maximise the footprint available—Consider maximising height, storage systems, materials handling systems, fire safety compliance, product staging, docks and manoeuvring space.

(5) Collaborative design approach—Partnering with experts in automation, refrigeration, and panel technology ensures that your cold chain system is designed for both maximum efficiency and future scalability.

Cold storage is rapidly becoming more automated, taller and demanding more space for staging of products for fast movement. Wiley in-house food and meat specialists partner with leading automation and refrigeration experts, ensuring every aspect of the cold chain is meticulously considered in the design, value engineering, construction and commissioning phases.

Looking to elevate your cold chain operations? Wiley offers comprehensive, end-to-end solutions, from feasibility through commissioning, to meet your unique needs. Connect with our experts to discover a customised approach tailored to your business. Partner with Wiley to integrate advanced design, technology, and construction, positioning your business at the forefront of the industry.

#Wiley #ColdChain #FoodSafety #Meat #Food #Innovation #ASRS #AutomatedStorageAndRetrieval #ColdStores #Tender #DesignAndConstruct #InsulatedPanel